- Homepage

- Sticker Printing

- Die-Cut Stickers

- Choose between singles & rolls

- Available in sturdy waterproof materials

- Add coatings for extra protection

- Square, rectangle, circle, oval, & custom sizes

Die-Cut Stickers

-

5 Star

(2)

-

4 Star

(0)

-

3 Star

(0)

-

2 Star

(0)

-

1 Star

(1)

Singles

Singles  Roll

Roll -

5 Star

(2)

-

4 Star

(0)

-

3 Star

(0)

-

2 Star

(0)

-

1 Star

(1)

Add a Touch of Branding to Your Products with Die-Cut Stickers

Create custom die-cut stickers to distinguish your products, or as freebies customers will appreciate. Apply them directly on your products or packaging whether it’s a box, bottle, or bag. Die-cut stickers are the ideal accent to your product packaging as they can help boost your brand’s visibility and attract potential customers. They’re printed in the exact shape you choose and indicate in your design. This makes it easy to peel off and apply directly for faster order fulfillments. You also save space for stacks that are displayed as free giveaways to customers in your store.

Our die-cut sticker printing comes in a variety of standard shapes and custom dimensions. We offer a broad range of available sizes to ensure that your stickers will fit your products perfectly. If you are planning to use your stickers indoors or outdoors, we have suitable materials available including BOPP and premium sticker paper.

How to Print Die-Cut Stickers Using the Price Calculator

Creating your custom stickers with a professional printing company like PrintPlace is fast and easy with the help of our price calculator and online design tool. Ready to get started? Follow these simple steps to create your die-cut stickers.

Step 1. Choose between singles or roll stickers.

Singles or cut-to-shape stickers can be peeled and applied by hand, ideal for small quantities. Roll stickers, on the other hand, are for labeling a large number of items and can be applied using standard-sized label dispensers.

Step 2. Select your preferred shape and size.

Our available standard sticker shapes include square, rectangle, circle, and oval. Both singles and roll formats are cut right to the shape you choose, but the former comes in separate individual pieces while the latter lines multiple copies in a roll. Both have several sizes that you can choose from.

Step 3. Set the quantity of your order.

The minimum number of pieces that you can order for our single stickers is 25. For roll stickers, the minimum is 250.

Pro tip: Order in bulk if you’re looking for cheap printing. The larger the order, the lower the unit price per sticker.

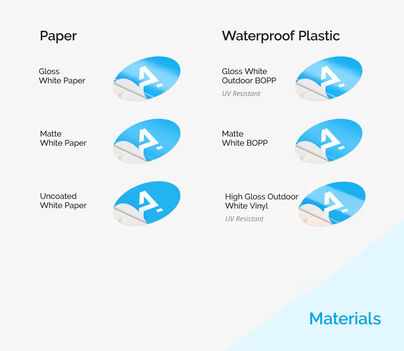

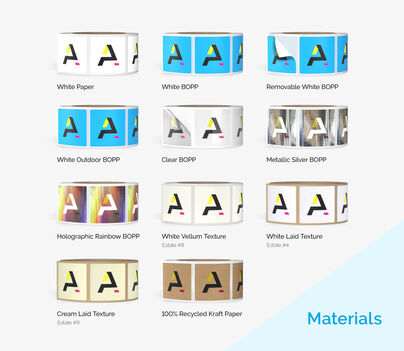

Step 4. Pick the material that is best suited to your needs.

- White premium sticker paper is writable and designed for indoor use.

- BOPP, an outdoor-friendly, water-resistant material, can withstand moisture.

- Textured stickers add elegance to product packaging, making them the perfect labels for wine bottles.

Step 5. Add lamination to your die-cut stickers to protect them from scratches and abrasion.

Go with either gloss for a vibrant sticker design, matte for a more subdued yet elegant look, or high-gloss UV coating for an eye-catching effect that is noticeable from a distance.

Step 6. Choose the unwind direction for your roll stickers.

This is to make sure your roll sticker will unwind based on the direction of the text printed on your sticker.

Step 7. Set your preferred production time.

Standard die-cut sticker printing time is five (5) business days. But if you want to rush the production of your single stickers, you can expedite it to 1-3 business days for an additional charge.

Step 8. Use the online design tool, download a template, or upload the print-ready file.

Create or upload a design from your preferred method. The design tool is recommended for those who don’t have a file yet and prefer an easy-to-use method to complete the custom die-cut stickers.

The “Layout Templates” tab offers files you can download straight to your device and open on the corresponding editing program.

If your file is ready to print, upload the file directly on our site. You can double check this reference to see if the PDF, PSD, PUB, or AI file fulfills all the print requirements. You can request to review the PDF proof online before production to ensure there are no errors.

Die Cut Stickers FAQs

How can I know the ETA of my die-cut stickers?

Click on Get Shipping Estimate below the price calculator and input your zip code to determine the expected time of arrival of your order.What are the requirements when uploading my file on your website for die-cut sticker printing?

It should be print-ready and in any of the following formats: PDF, JPEG, JPG, TIF, TIFF and EPS.Can die-cut stickers go on cars?

No, we don’t recommend applying die-cut stickers on cars. If you want to giveaway designs for customers to place on their vehicles, we recommend printing bumper stickers.What’s the difference between die-cut stickers and kiss-cut stickers?

Die-cut stickers are cut in the exact shape you specifyon the artwork file.Kiss-cut stickers come with a large backing sheet that makes the design slightly easier to peel. Unlike the die cut, the edges of the shape are protected and recommended for stickers given away in packaging.

Can I order sample stickers?

No, but you can order the minimum quantity per order, which is 25 pieces for our single stickers and 250 pieces for our roll stickers.Are your die-cut stickers water and oil-resistant?

We have die-cut stickers that are designed for both indoor and outdoor use. They are made from highly durable BOPP material, which is both waterproof and chemical-resistant.Die-Cut Stickers Layout Templates

Our layout templates also ensure that your die-cut stickers meet our printing guidelines. You may download the right layout template for your label in EPS, PDF, or JPG format